PLACEMENT EMPOWERMENT PROGRAM CAD & 3D PRINTING LAB

Co-ordinator of the lab

Dr. Vaddi Seshagiri RaoProfessor & Principal

St. Joseph’s College of Engineering, Chennai

Lab Incharges

Mr. N. SathishkumarAssistant Professor

Department of Mechanical Engineering

St. Joseph’s College of Engineering, Chennai

Dr. N. Thangapandian

Assistant Professor

Department of Mechanical Engineering

St. Joseph’s Institute of Technology, Chennai

Vision of the Lab

Equip the students to become professionals in 2D and 3D modeling packages which is further incorporated in creation of various complex shaped parts by using 3D Printing process.

Objectives of the Lab

Overview of the Lab

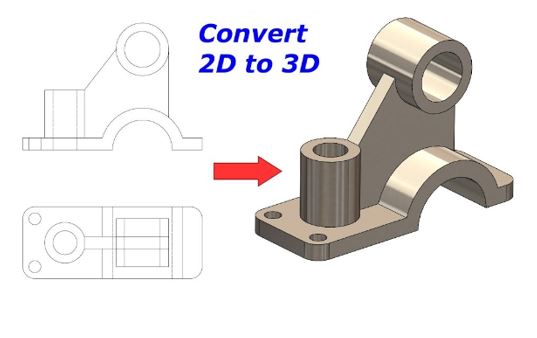

Computer Aided Design:

CAD programs (AutoCAD, Inventor, Revit, CATIA, SolidWorks, SketchUp) allow engineers to make precisely scaled drawings. These drawings can be used to manufacture equipment and construct infrastructure. CAD drawing allows designers to display designs with complete specifications and detail. Orthographic views (top, bottom, side, front, back, etc.) can be used to document every aspect of the technical drawing needed for production. Isometric views can be used to interpret the final 3D representation of the product.

This lab will train the components of CAD software, file formats, and the basics of 3D drafting. It will provide enough information to learn how to create drawings, as well as explore the other tools and functions.

3D Printing:

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer control, with material being added together (such as plastics, liquids or powder grains being fused), typically layer by layer.

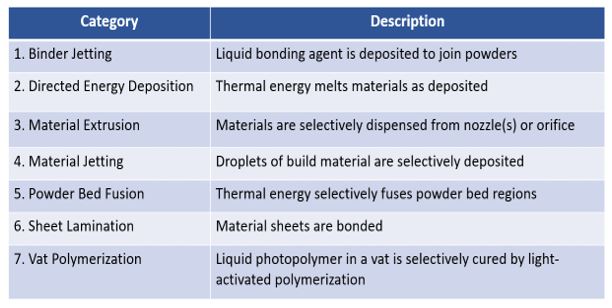

The various additive manufacturing techniques are as follows

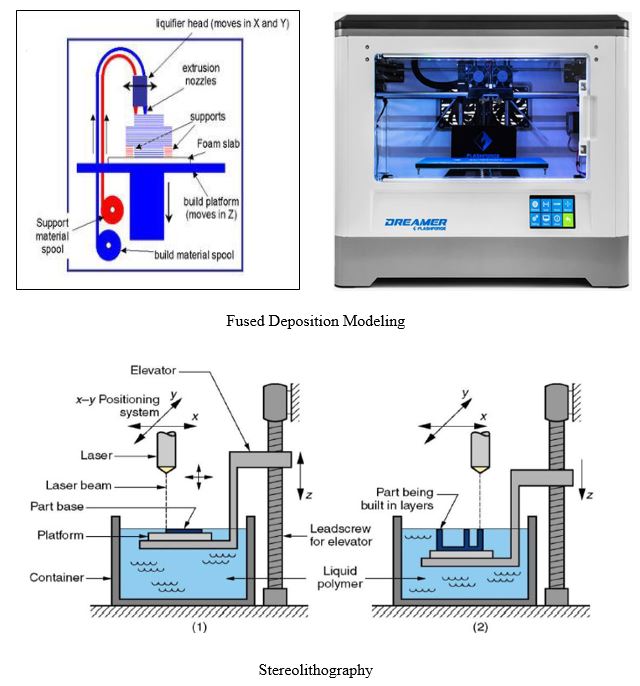

This lab will cover two types of additive manufacturing techniques

1. Materials Based – Fused Deposition Modeling

2. Vat Polymerization – Stereo lithography

Fused Deposition Modeling also known as Fused Filament Fabrication is an additive manufacturing process that contains a plastic filament or metal wire which is unwound from a coil and supplies material to an extrusion nozzle which can turn the flow on and off. The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a numerically controlled mechanism. The model or part is produced by extruding small beads of thermoplastic material to form layers as the material hardens immediately after extrusion from the nozzle. The schematic diagram of fused deposition modeling is shown below. Stereo lithography is an additive manufacturing process which employs a vat of liquid ultraviolet curable photopolymer resin and an ultraviolet laser to build part layers one at a time. For each layer, the laser beam traces a cross-section of the part pattern on the surface of the liquid resin. Exposure to the ultraviolet laser light cures and solidifies the pattern traced on the resin and joins it to the layer below. Scanning speeds ~ 500 to 2500 mm/s. Thinner layers provide better resolution and more intricate shapes; but processing time is longer. Starting materials are liquid monomers epoxies, acrylates (brittle). The following figure shows the schematic diagram of stereo lithography process at the start of the process, in which the initial layer is added to the platform and after several layers have been added so that the part geometry gradually takes form.

Course Outcomes

| S. No. | Description | Hours | RequiredKnowledge Level |

|---|---|---|---|

|

CO 1 |

To understand the basics of 2D modelling through Auto Cad software. |

20 |

Understand Apply Create |

|

CO 2 |

To understand the basics of 3D modelling through CATIA/SOLIDWORKS software. |

20 |

Understand Apply Create |

|

CO 3 |

To implement the basics of 2D and 3D modelling software for creating complex shaped parts through 3D printing Process. |

20 |

Understand Apply Create |

|

S.no |

2D Modelling (Theory and Practice) |

|---|---|

| 1. | Study Of Drawing Standards |

| 2. | Fits & Tolerances |

| 3. | Sectional Views, Hatching, |

| 4. | Dimensioning, Units, Scale. |

| 5. | Introduction to CAD |

| 6. | Wireframe modelling |

| 7. | Surface modelling |

| 8. | Synthetic curves, non-Uniform rational B splines, Fractal curves |

| 9. | Introduction To 2D Drafting Software (Auto CAD)-Limits |

| 10. | Auto CAD – BASICS |

| 11. | Layout And Sketching |

| 12. | Layer, Selection Methods, Osnap, Plotting |

| 13. | Drawing Environment |

| 14. | Elements Of Drawing |

| 15. | Draw Commands |

| 16. | Autolisp programming in Auto cad software |

| 17. | 2D – drawings for practice using Auto cad software |

| 18. | Isometric drawings for practice using Auto cad software |

| 19. | 3D modelling using Auto CAD |

| 20. | Allotment and Evaluation of Design Projects |

|

|

3D Modelling (Theory & Practice) |

| 1. | Parametric modelling |

| 2. | 2 ½D Modelling |

| 3. | First angle & Third angle Projection |

| 4. | Solid modelling techniques |

| 5. | CSG, B-rep, Sweep representations |

| 6. | Various CAD standards and file formats |

| 7. | Introduction of 3D Modelling software’s |

| 8. | Introduction To Catia V5 |

| 9. | The sketcher workbench |

| 10. | Profile toolbar |

| 11. | Operation toolbar |

| 12. | Sketch toolbar |

| 13. | Constraint toolbar |

| 14. | User selection filter toolbar |

| 15. | Visualization toolbar |

| 16. | Tools toolbar |

| 17. | Assembly Drawing |

| 18. | Overview of various other 3D modelling packages |

| 19. | Practice on CATIA V5 |

| 20. | Allotment and Evaluation of Design Projects |

|

|

3D Printing (Theory & Practice) |

| 1. | Need and Development of Additive Manufacturing systems |

| 2. | Additive Manufacturing process chain |

| 3. | Impact of Additive Manufacturing on Product Development |

| 4. | Virtual Prototyping & Rapid Tooling |

| 5. | Binder Jetting |

| 6. | Direct Energy Deposition |

| 7. | Material Extrusion |

| 8. | Material Jetting |

| 9. | Powder Bed Fusion |

| 10. | Sheet Lamination |

| 11. | VAT polymerization |

| 12. | Benefits & Applications of Additive Manufacturing |

| 13. | Introduction to Reverse Engineering |

| 14. | Digitization techniques |

| 15. | Model reconstruction & Data formats |

| 16. | Data interfacing, Part orientation and support generation |

| 17. | Support structure design & Model Slicing |

| 18. | Tool path generation & Software’s for Additive Manufacturing |

| 19. | Hands on training in 3D printers (FDM & SLA) |

| 20. | Allotment and Evaluation of 3D Printing Projects |

|

|

Additional tasks followed along with syllabus |

| 1. | Alumni and industrial mentors based mock interview |

| 2. | Expert alumni talk & Guest Lectures from industrial experts |

| 3. | In house workshops for practical training |

| 4. | Certification Courses in CAD and 3D Printing |

| 5. | Internship in reputed companies related to CAD &3D Printing |

| 6. | Consultancy Projects in CAD & 3D Printing |

| 7. | Filing design patents |

| 8. | Publishing journal papers in CAD & 3D Printing |

| 9. | Industrial visits to reputed CAD & 3D Printing labs |

| 10. | Ideation support for startup activities |

|

CAD & 3D PRINTING -STUDENT NAME LSIT |

||||

|---|---|---|---|---|

|

S.no |

Student Name |

Reg No |

College |

Department |

|

1 |

ANUPRIYA C |

312321103005 |

SJCE |

CIVIL |

|

2 |

SANTHOSH S |

312321103044 |

SJCE |

CIVIL |

|

3 |

SHAKTHI RAVIKUMAR |

312321103047 |

SJCE |

CIVIL |

|

4 |

SRINIVASAN M |

312321103051 |

SJCE |

CIVIL |

|

5 |

SATHISH KUMAR P |

312321103045 |

SJCE |

CIVIL |

|

6 |

MADHUSUDHANAN S |

312321103023 |

SJCE |

CIVIL |

|

7 |

LOGESH C |

312321103021 |

SJCE |

CIVIL |

|

8 |

NAVEEN S |

312321103030 |

SJCE |

CIVIL |

|

9 |

PRAGATESH KUMAR A L |

312321103033 |

SJCE |

CIVIL |

|

10 |

ASHWIN KANAKASAPAY |

312321103007 |

SJCE |

CIVIL |

|

11 |

VARSHINI R V |

312321103055 |

SJCE |

CIVIL |

|

12 |

JESSICA PREETHI B |

312321103015 |

SJCE |

CIVIL |

|

13 |

ISHANA MOHAN |

312321103013 |

SJCE |

CIVIL |

|

14 |

SAAYA SREE S |

312321103040 |

SJCE |

CIVIL |

|

15 |

SAN SERIN P |

312321103043 |

SJCE |

CIVIL |

|

16 |

NAVYA I V |

312321103031 |

SJCE |

CIVIL |

|

17 |

SIVARANJANI D |

312321103049 |

SJCE |

CIVIL |

|

18 |

SANJAI SRIRAM K |

312321114116 |

SJCE |

MECH |

|

19 |

SIVASUBRAMANIYAN A |

312321114127 |

SJCE |

MECH |

|

20 |

SREE HARISH M V |

312321114129 |

SJCE |

MECH |

|

21 |

SRIRAM KARTHICK |

312321114130 |

SJCE |

MECH |

|

22 |

SUBRAMANIYAN V |

312321114131 |

SJCE |

MECH |

|

23 |

SANTHOSH KUMAR C |

312321114119 |

SJCE |

MECH |

|

24 |

IRUTHAYA AGASTIN S |

312321114306 |

SJCE |

MECH |

|

25 |

THAMIZHSELVAN S |

312321114143 |

SJCE |

MECH |

|

26 |

IMAYAVARAMBAN A |

312321114050 |

SJCE |

MECH |

|

27 |

AMIRDHAVARSHINI U |

312321114014 |

SJCE |

MECH |

|

28 |

HARINI JV |

312321114046 |

SJCE |

MECH |

|

29 |

ABISHEK N |

312321114004 |

SJCE |

MECH |

|

30 |

THIRUMALAI KUMARAN S |

312321114146 |

SJCE |

MECH |

|

31 |

BARATH G |

312421114011 |

SJIT |

MECH |

|

32 |

SHARFARASH AHAMED |

312421114307 |

SJIT |

MECH |

|

33 |

GAYATHRI K. |

312321203012 |

SJCE |

CHEM |

|

34 |

KAVYA S |

312321203022 |

SJCE |

CHEM |

|

35 |

LINGA DHARANI V |

312321203027 |

SJCE |

CHEM |

|

36 |

MYSTERY PEARLY J |

312321203030 |

SJCE |

CHEM |

|

37 |

PADMASRI M N |

312321203033 |

SJCE |

CHEM |

|

38 |

PRADEEPA K |

312321203034 |

SJCE |

CHEM |

|

39 |

SAKTHIVEL A |

312321203043 |

SJCE |

CHEM |

|

40 |

SUBHASHINI K |

312321203053 |

SJCE |

CHEM |

|

41 |

K U UDAYASHAMINI |

312321203058 |

SJCE |

CHEM |

|

42 |

VIJAIDEESHMA V |

312321203061 |

SJCE |

CHEM |

|

43 |

GANESAN V |

312321203011 |

SJCE |

CHEM |